Skytex - ERP Software for Apparel and Home Textile Industry.

About Skytex

Running a textile production business isn’t easy. Between juggling inventory, managing orders, and keeping production on track, it’s easy for things to get messy. That’s where Skytex Textile ERP (Enterprise Resource Planning) software steps in—and it can change everything.

Skytex Textile ERP is a comprehensive software solution specifically designed for the apparel and home textile industry, streamlining every aspect of production and operations. From inventory management and order processing to production planning and quality control, it integrates all key functions into a single, easy-to-use platform. By automating workflows and providing real-time data visibility, Skytex helps textile businesses reduce errors, increase efficiency, and make faster, smarter decisions. Whether you're managing fabric sourcing, tracking garment production, or handling customer deliveries, Skytex ERP brings clarity and control to the entire supply chain—enabling your business to grow with confidence.

Why Skytex ?

- Managing business with standalone applications like accounting package and spreadsheet is highly inefficient.

- Delayed decision, reporting errors can lead to loss of business and reputation.

- Unified view gives full control that will transform your business.

- Real time data and single window information required for maximum efficiency and increased productivity.

- Management requires notification on overdue processes.

Transform Your Business with Smart ERP Features

A complete yet affordable ERP

A complete ERP to automate all your bussiness operations end-to-end without heavy investment.

Cost Saving

Requires no particular hardware/software configuration, additional maintenance and support cost, and highly paid IT staff. Moreover, works on `pay-as-you-go` subscription model.

Complete Security

Assures extemely secured environment with disaster recovery facility running 24X7.

Flexibility & Ease of Access to Service

Needs only web browser and network connection that can be accessed from desktop, laptop or mobile devices; anytime, anywhere.

Scalability

Easy start-up with a minimum number of users. MoreOver, flexible enough to increae number of licenses whenever required.

Peace of Mind Ensured

Automatic sofware upgrades, regulare data backup and 99.9% uptime with a supreme Disaster Recovery plan assues that system is always current, up-to-date up, running and always available.

Experience & Expertise to Stand Apart

ERP sans all those hitches of implementation and workarounds. Thanks to 30 years of experience in process manufacturing arena and a highly qualified plus exper task force.

Faster Time to Value

Makes your staff more productive, improves operational efficiency, and thus helps you realize ROI faster.

The Role of an Skytex ERP Software in Textile Manufacturing

Having laid out the typical manufacturing processes of textiles, it’s natural for you to wonder where an ERP software comes in. Here are some of the key areas a Skytex textile ERP software plays a vital role in garment production.

1. Data Management

Data silos not only stalls production planning but can also lead to costly errors with far-reaching consequences. As such, we can’t overemphasise the importance of data flowing smoothly across all your departments.

This is exactly where an Skytex ERP comes in useful, as it integrates every department—from procurement and production to finance and sales—into one unified system.

2. Efficient Order and Inventory Management

Whether you’re handling bulk orders, custom runs, or seasonal collections, an Skytex ERP system helps track material usage, stock levels, and order progress accurately.

3. Shop Floor Management

ERP systems provide live updates on production status on the production floor, which includes what’s being produced, where, and how far along it is. This allows you to monitor work orders in real time, identify delays, and make quick decisions to keep things moving.

4. Resource Allocation

By analyzing workloads and machine availability, an Skytex ERP helps optimize how labor and machines are utilized, reducing downtime and overloading.

5. Material & Inventory Synchronization

Skytex ERP ensures raw materials are available when needed. It keeps track of material usage on the shop floor, automatically updating inventory levels and triggering reorders when stock runs low.

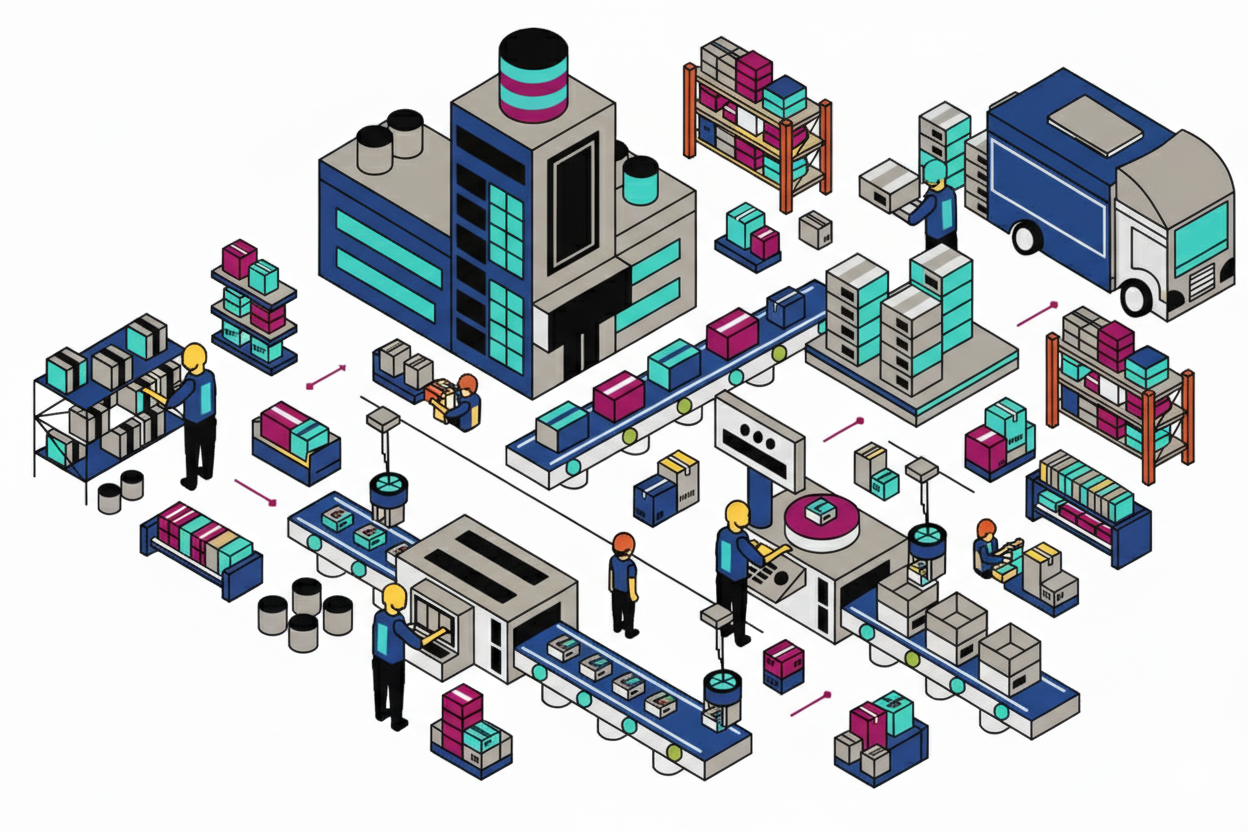

6. Supply Chain Management

An Skytex ERP system connects every stage of the supply chain—procurement, production, warehousing, logistics, and sales—in a single platform. This provides real-time visibility into stock levels, order status, and supplier performance, allowing businesses to respond faster to changes or disruptions.

Our Modules

CRM

Merchandising

- Costing Sheet generation for apparels and home textile products

- Enquiry response

- Consolidate list of Enquiries and follow-up action plans

- Purchase order

- Performa Invoice

- Testing standards update

- Packing format

- Consolidation list of PI with delivery date

- Fabric Allotment

- Trims Requirements

- Packing Accessories Requirements

- Product Finishing Allotment

- Shipping Parameters Allotment

- Product CAD and Artwork files upload

- Order Specification

- Test request generation

- Test reports update

- Order related information reports

- Production status based information reports

- This week and next week shipment order details with production percentage.

- T&A with status indication

Order Execution

- Quantity percentage (BOM vs GAN), amount percentage (Budget vs Billed), start date of activity and end date of activity.

- Summary Report

- Detailed Report

- Fabric width update after allotment completion

- Order Details

- PO Items

- DC Items

- GRN Items

- Location wise stock

- Bills

- Packing list generation based on stitching issued PCS

- Approval

- Consolidated list of packing lists

- Contract employees request

- Approval for Contract employee

- Contract employees payment

- GRN generation based on tailor based stitching entry

- P&L

- Incentives report

Procurement and Stores

- Prepare PO/JO (multiple parties, supply, payment and delivery terms, tax,)

- General and Stationary Items PO

- Approve PO/JO

- Escalate PO/JO

- Bulk PO/JO

- Pre-closure of PO/JO

- Manual DC for JOB orders

- Eligible qty validation based on PO/JO

- Auto DC for Accessories

- DC Approval

- Delivery confirmation

- GRN entry based on PO/JO.

- Eligibility validation for PO/JO

- GAN entry (First piece Approval validation)

- Auto debit note for late delivered goods.

- Return Items GRN entry

- Stock Transfer between stores and PI

- Approval

- General and Stationary items stock transfer to PI.

- Indent request generation

- Approval

- Physical stock based adjustments in stores

- Stock enquiry

- Stock Ledger

Quality Assurance

- First piece and Inspection status in percentage for live orders

- Yarn count report

- Colour fastness to rubbing/washing

- First piece approval

- Fabric Inspection report (4 Point System)

- Cutting first piece/Inspection

- Stitching first piece approval

- Bulk stitching Inspection

- Accessories receiving inspection

- Checking/packing online inspection

- Packing first piece

- Inline/Midline/Final Inspection report

- Sample box inspection

- Sample inspection report

- Inline/Midline/Final Inspection report

- Goods Receiving Inspection at every GRN entry

- Activity based GRI Parameter configuration option

- Non confirm products inspection

- Accepted and rejected products separation

- Debit note generation for rejected products supplier

- Stop payment to supplier if defect in product or fabric

- Defect rectification

- Payment release

Production Expenses – Accounting

- Supplier bills entry

- General bills entry

- Test request form bills

- Bill approvals

- Bill declined

- Payment authorization form (PAF) generation

- PAF approval

- PAF payment

- General voucher

- Reconciliation payment voucher

- Wages payment voucher

- Sample bill payment

- Wages bank payment sheet generation

- PAF bank payment sheet generation

- Ledger

- Day book

- Debit note

- Credit note

- Sales invoice generation for sales stock

- Consolidated list of sales invoice

- Receipt entry

- Wages payment sheet

- Wages payment sheet approval

- Manpower payment sheet

- Weekly requirement

- Weekly requirement summary

- Wages payment activities reconciliation

- Bill payment activities reconciliation

- Purchase orders reconciliation

- Auto reconciliation once shipment completed

- Reconciliation approval

Financial Accounts

Lab

Knowledgebase

- Category creation

- Files upload – Define access users for the file to access

- Files download based on authorization

knitting

Dyeing

Stenter

Mechanical Finish

Final Inspection

Finished Warehouse

Cutting

Stitching

Packing

Component Warehouse

Socks

Documents

- Generating final packing list

- Approval

- Drawback received amount entry

- Consolidated list of Drawbacks received

- Lorry invoice

- Lorry invoice approval

- Commercial invoice

- Commercial invoice approval

- BL

- Shipping Bill

- Forwarding charges

- Clearance charges

- MEIS received amount entry

- Consolidated list of MEIS received

- Customer payments entry

- Consolidated list of Customer payments received

- ECGC registration

- ECGC statement generation

- Marine insurance

- Insurance Ledger

SMS

Asset & Maintenance

Sampling

- List of product styles with image

- Search option based on style no, season, order price, customer and date

- Design / Initial / Testing sample orders.

- PP sample orders.

- Activities selection

- Budget

- Sample PO

- Sample DC

- Sample GRN

- Sample Bill

- Cutting size chart upload

- Weaving patter sheet upload

- Packing list generation

- Packing list approval

- Stickers generation

- Courier details entry

- Sample shipment approval

- Mail to customer with courier details and sample images

Utilities

KIOSK

IIOT (Industrial Internet of Things)

Admin

- Activities

- Accessories

- Approvals

- Category

- Buying house

- Company

- Currency

- Customer

- Documents

- Transport

- Employee

- Factory

- Item

- Inspection Unit

- Main ledger

- Sub ledger

- Payment terms

- Delivery terms

- VAT / CST / Excise duty

- Store

- Supplier

- MP supply unit

- Testing agency

- Test protocol

- Units

- Approval users configuration (Level based or Multiple)

- Preferences (GRN excess allowed percentage, retention percentage etc..,)

- Yarn count, knots, hanks and hank weight details

- Day preference (PO/JO approval method, SMS enable etc..,)

- Supplier opening balance

- Inspection employee allocation

- GRI parameters

- Auto task

- Urgent news

- News and events

- News

- Vision

- Our pledge

- Access rule to define based on activities.

- User creation (Employee login and customer login).

- SMS log

- Email Log

- SMS templates

- Category

- Sample type

- Order conversion status

- Product type

- Country

Reports

- Production summary

- Production details

- Merchandising

- Order Execution

- Stores

- Production Expense

- QC

- Management

- ERP

- Task

- Documents

Customer Portal / IP Restriction

- Orders Timeline

- This week shipments

- Activity wise order progress status

- Packing status based on stitching issue (short qty and extra qty)

- Activity wise production and T&A details in percentage display

- Ongoing orders list.

- Completed orders list.

- Restriction to access the application within home network IP.

- Setup home network IP in configuration.

- Setup different access rule for other location. (Ex: Give only report access).

Business and Functional Advantages.

Key Businees Benefits

- A SaaS-based complete ERP for textile manufacturers

- Handles all business operations from Merchandising, Manufacturing, Finance to Quality & Compliance

- Enables access from anywhere and at anytime using Internet connectivity.

- Requires no heavy expenditure, no hassles of data security, no time consuming installations, and ensures zero downtime

- Regular data-backups and disaster recovery support.

- Industry based expert panel for implementation and enhancements.

- Higher Operational Efficiency.

- Lower operating cost.

- Get accurate information to take critical business decisions.

Key functional Benefits

- Centered around management information system to handle business effectively and efficiently.

- Easy and flexible to operate web application.

- There's no more searching the paper file page by page.

- Generate Costing in less than 5 Minutes.

- Responsive design to operate application in Tablet, mobile.

- Staff will spend less time filing and tracking down and managing files.

- Detailed demographical and business data analysis.

- Flexible and comprehensive reports classification to get accurate information.

- Legible, accurate and complete documented records result in further reduced risk and malpractice exposure to clinicians, hospitals and the company.

- Compatible with any web browser.

Frequently Asked Questions

-

What is textile Erp ?

Textile ERP software is a comprehensive business application that meets the demand for continuous improvements in the textile manufacturing business. The implementation of ERP software helps textile manufacturing units to remain competitive in a global market. It enables textile mills to improve production quality, reduce quality errors, increase time-to-market, and respond without issues to seasonal fluctuations in demand.

Textile ERP has modules for every function that is under operation in textile mills. The key modules take care of procurement, production, inventory, accounting, financials, compliance, maintenance, supply chain, warehouse, and customers. With customizable textile ERP software solutions, manufacturers can add or drop the features that they need or don’t need as per their respective manufacturing unit requirements.

ERPs work by automation, and automation mitigates redundancies and waste processes. Automation brings lean manufacturing into existence and thus helps manufacturers save big on time, effort, and money.

The ERP for textiles also covers the business intelligence aspect. Analytics are very prominent today in the world where data exerts a huge influence on how businesses work, earn, and stay ahead of the curve. Textile manufacturers can get reports and analytics with easy-to-visualized reports about the key happenings in their business (from sales to dispatch and financial reports to inventory status). These reports help textile manufacturers take timely action to improve their businesses.

From small textile units to medium and large-scale textile manufacturers, textile ERP is adaptable and scalable to cater to all sizes of textile manufacturing businesses.

-

What are the challenges textile manufacture face ?

Challenge 1: Complex Supply Chain Management

Solution: ERP for textile eases supply chain operations with optimized route mapping, inward/outward tracking, and warehouse management

Challenge 2: Quality Assurance

Solution: Ensure quality control with quality check parameters and inspection tools.

Challenge 3: Machinery Downtime

Solution: Automated proactive maintenance scheduling to maximize uptime.

Challenge 4: Inefficient Communication

Solution: Textile software offers a centralized platform for inter-departmental communication, file sharing, etc.

Challenge 5: Financial Management

Solution: Generates accurate financial reports, GST reports, filings, expense statements, P&L statements, etc.

Challenge 6: Demand Forecasting

Solution: Utilizes historical data to predict market requirements and plan production accordingly

Challenge 7: Cost Management

Solution: With the automation of redundant processes and lean manufacturing to reduce waste, the ERP for textile leads to significant cost savings

Challenge 8: Inventory Management

Solution: Stock operations simplified with inventory, warehousing, stock verification, and barcoding features.

Challenge 9: Supplier and Customer Relationship Management

Solution: Collect data of suppliers and customers in the contact module and use them for promotions or faster connection with these stakeholders.

Challenge 10: Procurement management

Solution: Helps strategize raw material requirements, generates Bills of Materials, and automated reorder points

-

How long it will take to implement ?

Textile ERP implementation by VasyERP is a simplified process that is designed to remove pain points, delays, and unnecessary steps. Our textile ERP implementation duration is the fastest as it could be and the duration varies as per the size and scale of your textile unit. The implementation also depends on what features, customizations, and added services you require. the features required and current process complexities. However, VasyERP ensures the fastest possible implementation due to its years of expertise in ERP solutions for manufacturers.

-

How to choose best ERP for textile industry ?

Textile manufacturing industry has complicated workflows. Without the selection of the most suitable ERP and a flawless implementation, the textile manufacturer cannot reap the benefits offered by the ERP. Generally, there are thousands of ERP providers that pitch their services as the best and claim their features are unbeatable. However, the situation is far from reality. Many have either extremely expensive services or they lack custom features. Some are mediocre and some are even low quality. Textile manufacturers may also face post-implementation issues or poor customer support. Then there are issues with the privacy of data, hidden costs, poor integrations, and the list goes on. This may cause textile manufacturers to regret their decision for ERP implementation. Therefore, choosing the most suitable textile ERP software is paramount for actual success and worry-free implementation. To choose the best ERP for textile manufacturing, consider the following steps:

Know what you need: Ignorance is not bliss when it comes to selecting textile ERP. You may lose money if you don’t know exactly what your current requirements are, and what type of supply chain features, inventory features, or accounting modules you need to keep your textile unit running profitably. Understand the intricacies of production planning, and quality control. Seek an ERP that addresses all pain points and your specific needs.

Integrations and modules: Efficient Textile manufacturing is a sum total of multiple processes going on in a synchronized way. This means, your procurement, production, inventory, supply chain, CRM and finance must be interconnected for a smooth flow of data between these processes. Such integration is the only way you can keep all departments on the same page and remove departmental or process silos. involves various interconnected processes such as design, production, inventory management, accounting module, and sales. Ensure that the chosen textile ERP has seamless integrations.

User-Friendliness: Not all your staff will be super tech savvy and any ERP that demands a lot of learning curve can repel your staff. With complicated dashboards, your staff may face issues with understanding how to read the data on the screen. This will fail the purpose. Ensure your textile manufacturing software provider guarantees an intuitive and user-friendly interface that can be navigated without hiccups.

Expertise of the Provider: Check how much experience, expertise, domain knowledge, and understanding of the industry challenges your ERP provider has and whether they would be able to serve you. This evaluation can be done just by going through their demo and asking them questions. Ask about how their ERP will tackle seasonal fluctuations, supply chain complexities, etc.

Customization: In textile, though every mill has the same processes the scale or workflows can be different. Custom features that specifically address this disparity and uniqueness are essential. Therefore, simply ask your textile ERP provider if they provide custom features or not. Consider the refusal of custom features as a red flag. However, if they explain the feasibility issues due to certain limitations then pay attention, as they may be rational. It means that there are actually some features that cannot be custom-implemented due to certain limitations.

Consideration of Costs: Finally, the cost is where things are finally settled. Evaluate the cost quotations, but also keep quality in mind. Vendors with great teams, better responsiveness, and experience will also demand a premium on their services but the value you receive will be equally greater. Understand implementation costs, operational costs, licensing fees, training and support costs, etc. before you make the final investment.

-

What is best ERP for textile industry ?

The best textile manufacturing ERP provides scalability, top features, and custom options, all within a reasonable budget. Skytex offers one of the best textile ERP solutions that meets all these criteria. Skytex comes with a comprehensive set of features tailored specifically to the needs of the textile industry.

-

What sets Skytex Textile ERP apart from other ERP solutions ?

Skytex ERP stands out as an ERP for textile and manufacturing industry. It’s tailored to industry-specific needs with modules like Production Management, Lab Dips, Recipe Management, Fabric Sampling, and more, streamlining textile business operations.

-

What kind of support can I expect during and after the implementation ?

We offer comprehensive support during and after implementation with our ERP for textile industry. This includes assistance with system setup, data migration, user training, and ongoing technical support. Customer support teams are available 24/7 to help you resolve any technically issues promptly.

-

Can Skytex Textile ERP integrate with my existing applications and systems ?

Yes, Skytex textile manufacturing software is designed to help you manage operations in multiple business locations, languages, units of measurements, tax situations, and support transactions in multiple currencies.

-

Is Skytex Textile ERP a cloud-based or on-premise solution ?

Our ERP software for the textile industry is a 100% cloud-based solution that you can access right from your browser. It gives you flexibility, anywhere access, and eliminates maintenance costs.

-

How scalable is Skytex Textile ERP ?

Skytex's textile manufacturing ERP software is a highly scalable solution, designed to adapt to your business's growth and evolving requirements. As your company expands, the system can seamlessly accommodate additional users, departments, and functionalities.

-

Can Skytex Textile ERP help with regulatory compliance in the textile industry ?

Yes, we have designed an advanced traceability and sustainability solution designed to help all fashion businesses visualize their global supply chain, manage certifications, audit statuses and communicate compliance with buyers. The solution integrates seamlessly with our ERP for textile and apparel industry—giving you access to accurate reporting and complete visibility.

-

Is Skytex ERP capable of generating customized reports for management?

Yes, Skytex ERP is fully capable of generating customized reports for management. The system allows you to create reports tailored to your specific needs, including production performance, inventory levels, sales trends, financial summaries, and more. With SkytexERP, management can access real-time data in an easy-to-understand format, enabling faster decision-making, better resource planning, and improved overall efficiency.